A

Unlike leaded components, chip components are susceptible to flexing stresses since they are mounted directly on the substrate.

They are also more sensitive to mechanical and thermal stresses than leaded components.

Excess solder fillet height can multiply these stresses and cause chip cracking. When designing substrates, take land patterns and dimensions into consideration to eliminate the possibility of excess solder fillet height.

There is a possibility of chip cracking caused by PCB expansion/contraction with heat, because stress on a chip is different depending on PCB material and structure. When the thermal expansion coefficient greatly differs between the board used for mounting and the chip, it will cause cracking of the chip due to the thermal expansion and contraction.When capacitors are mounted on a fluorine resin printed circuit board or on a single-layered glass epoxy board, it may also cause cracking of the chip for the same reason.

*For each individual warranty information, please review our product specifications or consult the approval sheet.

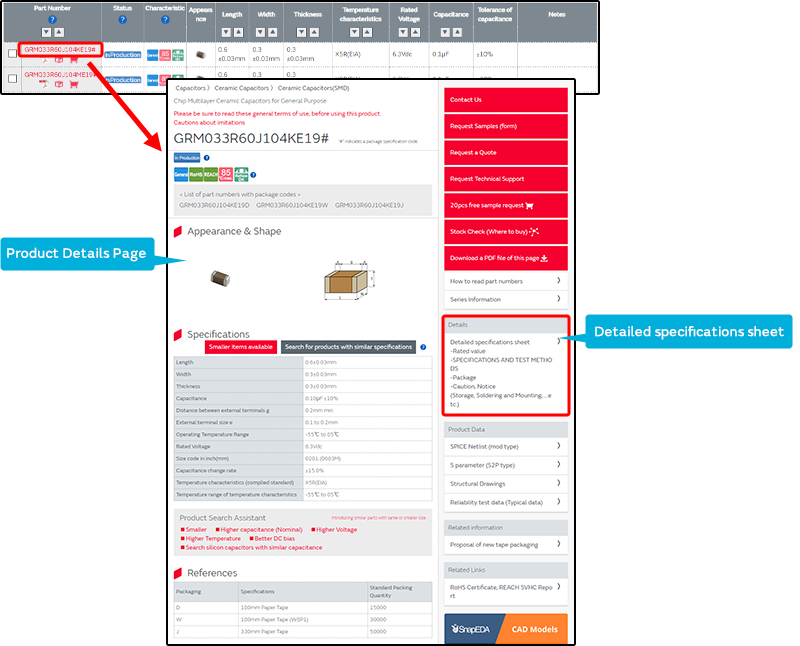

For more information of main products, please check the detail spec sheetDetailed specifications sheet

on our website.

on our website.

Ceramic Capacitor Product Search

<Related data>

my Murata - Capacitor site “Application Manual -Board bending stress”

(You need to create an account with your company email address, log-in, request access to each site, and get a membership.)