An excessive amount of flux generates a large quantity of flux gas, which can cause a deterioration of solderability, so apply flux thinly and evenly throughout. (A foaming system is generally used for flow soldering.)

Flux containing too high a percentage of halide may cause corrosion of the outer electrodes unless there is sufficient cleaning. Use flux with a halide content of 0.2% max.

Strong acidic flux can corrode the capacitor and degrade its performance.

Please check the quality of capacitor after mounting.

*For each individual warranty information, please review our product specifications or consult the approval sheet.

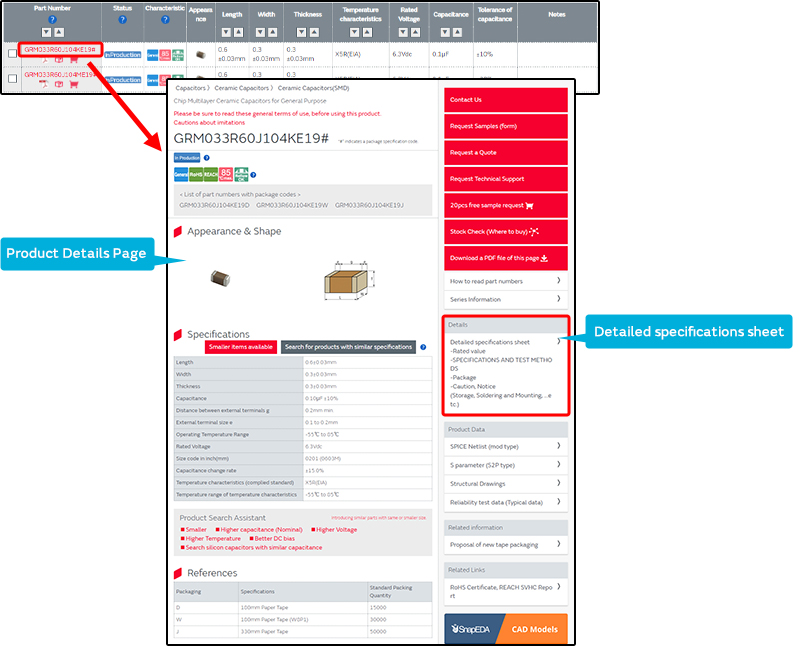

For more information of main products, please check the detail spec sheetDetailed specifications sheet

on our website.

on our website.

Ceramic Capacitor Product Search