A crack may be caused in the capacitor due to the stress of the thermal contraction of the resin during curing process.

The stress is affected by the amount of resin and curing contraction.

Select a resin with low curing contraction.

The difference in the thermal expansion coefficient between a coating resin or a molding resin and the capacitor may cause the destruction and deterioration of the capacitor such as a crack or peeling, and lead to the deterioration of insulation resistance or dielectric breakdown.

Select a resin for which the thermal expansion coefficient is as close to that of the capacitor as possible.

A silicone resin can be used as an under-coating to buffer against the stress.

Select a resin that is less hygroscopic.

Using hygroscopic resins under high humidity conditions may cause the deterioration of the insulation resistance of a capacitor.

An epoxy resin can be used as a less hygroscopic resin.

The halogen system substance and organic acid are included in coating material, and a chip corrodes by the kind of Coating material. Do not use strong acid type.

*For each individual warranty information, please review our product specifications or consult the approval sheet.

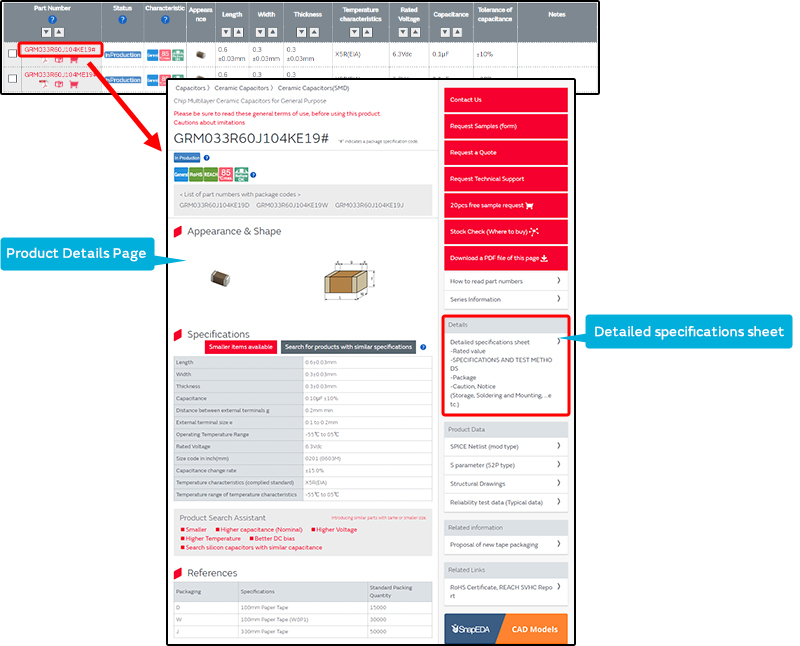

For more information of main products, please check the detail spec sheetDetailed specifications sheet

on our website.

on our website.

Ceramic Capacitor Product Search