Protecting our supply chain from conflict-affected minerals

Global companies often rely upon extremely long supply chains that draw in raw and partly finished goods from all over the world. The upside of this approach is that it enables the extremely specialised production processes that have been favoured by economists since the eighteenth century. The downside is that it can make it difficult to know exactly where suppliers are sourcing the materials from, and what impact the extraction of those materials is having on the local people, economy, and environment.

Resource extraction has often involved disputes over ownership rights, the exploitation of labour, and environmental damage. By the end of the twentieth century, it seemed as though, for many, these issues had faded into history, become something that only happened during the scramble for iron, coal, and wood to fuel the first Industrial Revolution. Then, during the first decade of the 21st century, they came roaring back into our lives, our homes and even our pockets as reports started emerging of wars being waged over metals for use in cell phones and other electronic goods. There were continuing conflicts in the Democratic Republic of Congo and the Great Lakes region of Africa over ‘coltan’, the mineral ore from which tantalum, used in high-performance capacitors, is extracted. Tantalum was soon grouped with tin, tungsten, and gold to become known as 3TG conflict-affected minerals, extracted under duress in appalling conditions.

Users of these materials knew that doing so was morally wrong. They also began to realise that doing so also created a huge reputational risk. And soon enough, laws emerged to insist that companies that bought these materials investigated how they were sourced. The challenge remains in driving conflict-affected minerals out of the supply chain. After all, once it has been processed, gold is gold is gold, lacking any characteristics with which it could be identified as sourced in unethical ways. And so we have to rely on a mix of industry, NGO and governmental monitoring and accreditation schemes, contract clauses and corporate policies to help us keep our supply chain free of conflict-affected materials.

Corporate Social Responsibility (CSR)

For example, Murata has a Corporate Social Responsibility (CSR) procurement initiative, which is expressed through a procurement policy and code of conduct. Our basic procurement policies call for us to comply with the law, act fairly, be impartial and honest, and tend to our social responsibilities. Our code of conduct then calls for, among other things, environmentally conscious material procurement, respect for human rights and consideration of the local environment, and promotion of a responsible approach to mineral procurement.

‘Regarding the procurement of minerals contained within materials, we have a stated response policy which we strive to carry out. We promote activities with respect to "the achievement of conflict-affected free materials in delivered products" such as establishing and putting into practice an internal control system, surveying the supply chain and carrying out due diligence, and procuring materials only from RMAP conformant smelters.’

Murata’s Supply CSR procurement guidelines go into more detail about the issue, stating that suppliers should have a policy for responsible minerals procurement to ensure that any tantalum, tin, tungsten, gold, or cobalt used in their products “does not directly or indirectly finance or benefit armed groups that are perpetrators of serious human rights abuses in the Democratic Republic of the Congo or an adjoining country.”

Policy made public

Suppliers are also required to make the policy public on their website, follow the OECD’s

Due Diligence Guidance, and only procure 3TG and cobalt from smelters that have been certified as conformant by third-party auditors. It also says that suppliers should exercise due diligence about the source and chain of custody of the materials and should be prepared to make these due diligence measures available to customers upon request.

Murata surveys its suppliers to understand how quickly they are coming into line with our requirements. In 2021, for example, we surveyed 154 main suppliers handling 3TG and achieved a 100% response rate to identify 359 smelters. Moreover, in the cobalt survey of 91 companies, the response rate was 86% to identify 61 refiners.

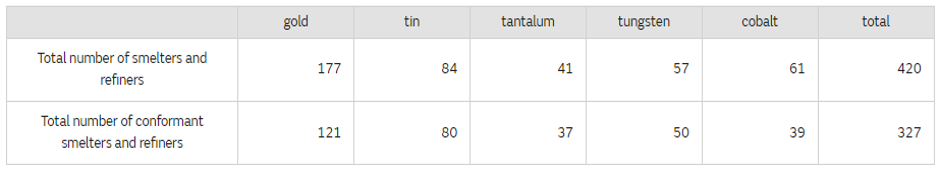

We focus so much on the refiners because it is in their facilities that the metals we use are decoupled from their source minerals by the smelting and refining processes. We look for refineries that belong to some sort of auditing and accreditation scheme, such as the Responsible Minerals Assurance Process run by the Responsible Materials Initiative. The table below shows that, although for materials such as cobalt the uptake of RMAP accreditation amongst our potential suppliers still has some way to go, overall, 78% of the suppliers we surveyed do use the scheme.

Ensuring our supply chain is free of conflict-affected materials requires a continually evolving combination of corporate policies, codes of conduct, supplier requirements, engagement with industry initiatives, and so on. While this can take time and resources, it enables us to steadily improve our understanding of our supply chain and to become increasingly confident that we are not, directly or indirectly, contributing to the modern scourge that is conflict-affected-affected mineral extraction.