Enabling the EV revolution

Engineering advances over the past decade have seen vehicle electrification claim its place as an essential building block for a sustainable future. Electric vehicles (EVs) are already central to global efforts to decarbonise the automotive industry and restrict global warming to 1.5°C as outlined in the Paris Agreement and reaffirmed by the COP26 summit. However, it’s not just the environmental aspect driving their popularity. Recent advances in battery technologies, together with the reducing cost of purchase and ownership, the introduction of a broader range of models, and the improving availability of charging infrastructure have accelerated adoption. It is evident that the demand for EV solutions is strong and growing; in 2020, when overall automotive sales were shrinking, EV sales increased by 67% from the previous year, according to World Resources Institute.

In line with this growth, the technological progression in the EV space continues to pick up the pace. From various electrical components to safety technologies and battery development, the industry strives to optimise the vehicles to create a safer, more reliable, and more comfortable driving experience. Murata is proud to play a vital role in facilitating this progress through its safety capacitors. These crucial components are used throughout modern EV powertrains, for example, in onboard chargers (OBCs), traction inverters, and DC-DC converters. They are employed for various purposes, including common mode filtering and isolation, to enable electromagnetic interference (EMI) suppression or provide protection from voltage transients.

Providing the right components

With nearly a quarter of a century of experience with Murata, Toshio is well-placed to say what makes it a great company to work for.

In the future, powertrain voltages are set to rise to support more advanced vehicle designs, allowing higher power/volume ratios and increased efficiencies. Meeting these requirements calls for a new breed of components. With decades of experience in developing capacitors to meet the evolving requirements of the automotive sector, Murata is well-placed to support the current and future needs of the market. The company is constantly expanding its capacitor range which has been enhanced for EV deployment and complies with the requirements of the IEC60384-14 Y2 international safety standard and the AEC-Q200 automotive standard.

The DE6 series is an excellent example of capacitors designed to address the needs of EV manufacturers. The range offers a highly effective through hole technology (THT) solution with capacitance from 100pF to 4.7nF. The highly compact 300VAC-rated Class X1/Y2 components can support higher temperature operation than film capacitors.

The vision for Murata was set by Toshio together with his predecessor. Murata strives to be the company of choice for modules and solutions and a real innovator in electronics.

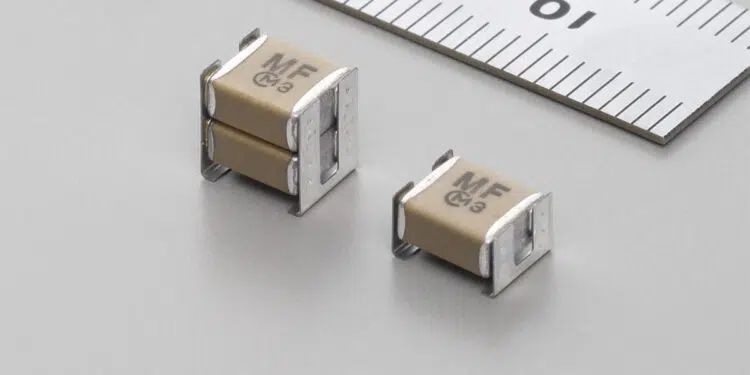

The KCA series of multi-layer ceramic capacitors (MLCCs), on the other hand, takes space optimisation even further. The high-density construction results in significantly smaller case sizes, allowing engineers to save valuable board space while the surface-mount design simplifies production. Other advantages include a very low equivalent series resistance (ESR) and equivalent series inductance (ESL) figures, key attributes from a noise suppression perspective. Another significant benefit of the KCA series is its reliability. The metal bow construction of the capacitors substantially reduces the stress put on the ceramic element, allowing them to withstand higher board deflection and heat conditions. Tests have also shown that this construction also minimises risks arising from vibration.

Link to Passive Components platform article: https://passive-components.eu/murata-safety-ceramic-capacitor-solutions-for-ev-powertrains/

The future is electric

To meet the ambitious targets set out in the Paris Agreement (Climate Action Tracker 2020 report), fully electric vehicles will need to account for 75-05% of global annual passenger vehicle sales by 2030 and 100% by 2035. Meeting these goals requires the EV market to continue exponential growth and electronics and parts manufacturers to enable it through fresh innovation. Murata is already ahead of the curve. Anticipating the market's requirements, the company has been developing a new range to meet the needs of even higher voltage powertrains. More details of the new products will be available in Q2.

For more information, visit www.murata.com.