Tackling food shortages with data-driven farming

With the global population expected to hit nearly ten billion by 2050 , the agricultural industry is set to see unprecedented pressure with almost two billion more mouths to feed. The population growth adds to other challenges the sector is already struggling with, including limited land reserves, workforce issues and various environmental factors. Faced with a serious risk of global food supply shortages, the industry needs to develop more efficient methods to keep up with the demand whilst advancing sustainability across the sector in line with the UN’s Sustainable Development Goals (SDG). This is where the latest advances in sensor technology can play a crucial role, enabling farmers to leverage data to enhance the way they cultivate their crops to optimise productivity.

Moving towards a data-driven approach to agriculture brings several advantages. By deploying sensor devices across the farming sites, farmers can gain accurate real-time information on the parameters that have the most significant impact on their crop yields, such as humidity and air temperature. This will give them better control over the changing circumstances, allowing quick corrective or protective action when something is amiss and providing insight to guide well-planned future development. Making some of the key processes more efficient will contribute to several of the goals outlined by the UN, including ending hunger, providing better access to clean water and sanitation, and promoting sustainable use of terrestrial ecosystems.

Sensors can help improve some areas that add to the operational cost for farmers, such as irrigation and fertiliser use, as well as lighting in indoor and vertical sites. However, the farming environment sets strict requirements for the technologies utilised in order for them to deliver on their potential.

Measuring soil conditions

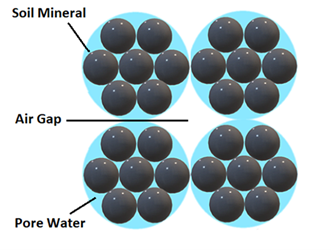

One of the applications where sensor technology can reap the most significant benefits is soil analysis. Through sensor data, farmers can track the amount of nutrients and salt in the soil, monitor rainfall or irrigation systems, analyse the quantity of fertilisers used, and keep an eye on potential risks such as groundwater pollution.

Yes, despite their benefits, several challenges are associated with existing soil sensor devices. Temperature variations, excessive water content, and the presence of chemical compounds can affect their accuracy, while any rocks between the sensor’s electrodes can interfere with the results. Inaccurate readings can result in miscalculated actions, putting the crops at risk.

3-in-1 technology

Looking to overcome these issues, Murata’s engineering team developed a new, more advanced soil sensor. With three sensing functions built in, the highly integrated device enables farmers to monitor three critical parameters simultaneously and continuously. The solution consists of:

1. A nine-electro sensor element, via which EC can be determined.

2. A moisture sensor element that measures electrical permittivity to give a value for the volumetric water content (VWC) figure.

3. A temperature sensor element.

The nine-electrode EC sensor is unique to the industry. It offers considerably improved accuracy by generating multiple measuring patterns, helping eliminate any uncertainty in the results derived. The moisture sensor covers a VWC range from 0 to 60%, with full-scale accuracy of ±3%. Similarly, the temperature sensor supports a range of -20°C to 60°C with accuracy of ±1.0°C. It leverages a proprietary algorithm to compensate for temperature influences on the EC measurements. Another proprietary algorithm is used to measure fertiliser content, enabling the device to provide accurate data on over-usage.

Cost-effective solution

Crucially, as large fields may require high sensor density, the cost per unit can’t be prohibitive. Murata’s soil sensor devices take this into account, offering high accuracy while remaining more cost-efficient than other solutions on the market.

The robust IP68-rated enclosure ensures the sensor can withstand the harsh environmental conditions it is subjected to, protecting it from dust and moisture. It comes with a choice of UART, RS232E, RS485-MODBUS and SDI-12 wireline interface options, and support for wireless connectivity is available through a Bluetooth LE transceiver. For optimal ease of use, the data acquisition times are simple to adjust. The sensor also requires minimal maintenance, with three AA batteries capable of powering it for at least six months before needing replacing.

To ensure its viability in a range of agricultural scenarios, Murata successfully carried out extensive testing in locations across Asia. Applications included evaluating the salinity levels in rice fields, analysing fertiliser use in fruit farming and monitoring irrigation efficiency in peanut orchards. Through these and other use cases, the sensors help farmers develop more sustainable practices in line with the Sustainable Development Goals, for example, by improving crop yield (#2 Zero Hunger), preventing groundwater pollution (#6 Clean Water and Sanitation), and enabling soil condition restoration (#15 Life on Land)

Preparing for future challenges

As the above examples demonstrate, leveraging sensors to move towards more data-driven methods can help mitigate many of the current and anticipated challenges in the food supply chain. New innovations, such as Murata’s 3-in-1 soil sensor, play a key role in helping the farming industry develop more strategic approaches to increase productivity, enhance sustainability and make the most of limited resources.

Source: https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html

For more info, click here

Press release: https://www.murata.com/en-eu/news/sensor/others/2019/0122