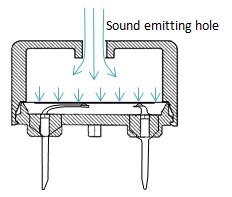

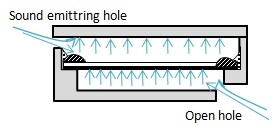

1. High pressure air should not be blown to "Sound emitting hole" or "Open hole" of a Piezoelectric Sounder or a Buzzer.

In the case high pressure air is blown to "Sound emitting hole" or "Open hole", the crack occurs on diaphram, and it may cause "Low sound" or "No sound". Or, there is a possibility to blow away the cap from the product.

|

|

| Pin Type |

SMD Type |

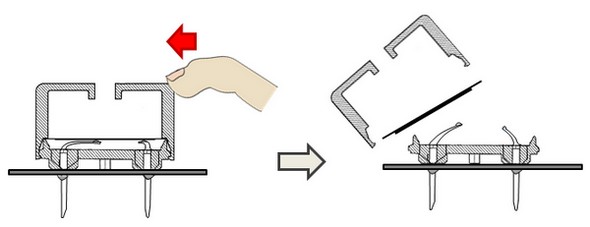

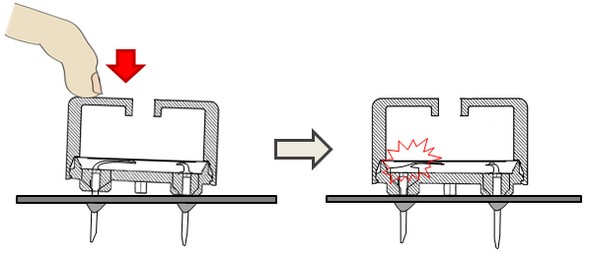

2. Please don't press the product after soldering.

2-1.

In the case they are soldered in the state with tilted, the terminal is forced by pressing the product, and it may cause "Low sound" or "No sound".

2-2.

2-2. There is a possibility the the case will be come off if external stress is given to the product after soldering. Once the case comes off, do not reassemble. Please replace to the new one.