Developing New Sensor Devices Utilizing Piezoelectric Property of Polylactic

Acid

Demands for smartphones and tablet PCs equipped with gesture recognition touch panels are skyrocketing. In

attempt to differentiate their products, equipment manufacturers are looking for new types of human-machine

interfaces (HMI). Organic piezoelectric films, with its flexibility and ability to generate signals from a

variety of actions, have a high potential for such a new type of HMI implementations. Murata has developed a

unique sensor to take advantage of shear piezoelectricity*1 in a non-pyroelectric piezoelectric polymer,

polylactic acid.

What is Polylactic Acid?

Since around 1995, polylactic acid (PLA) became known as an all-purpose biodegradable polymer*2 with the strength and formability equivalent of

petroleum resins. Now, PLA is widely known as an eco-friendly polymer. Unlike other biodegradable

polymers, PLA has excellent light transmittance exceeding acrylic's 93%. PLA is sometimes used as

packaging material for eggs and tomatoes at grocery stores. Although it is commonly known as an

inexpensive and eco-friendly plant-origin polymer, Murata has focused on PLA's piezoelectric property.

Piezoelectric Property of PLA

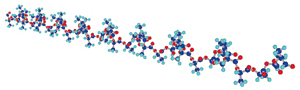

Lactic acid monomer, a chiral*3 molecule, has

two optical isomers whose molecular structures cannot be superimposed with each other. Such isomers

are called L-isomer and D-isomer. A left-handed helical polymer consisting of L-isomers is called

poly-L-lactide acid (PLLA) and a right-handed helical polymer consisting of D-isomers is called

poly-D-lactide acid (PDLA) (Fig. 1) .

Fig. 1 Molecular structure of PLLA

A film made of these PLA polymers (in this case PLLA) , when uniaxially drawn to orient molecules, is

known to display piezoelectric property. Jointly with Kansai University and Mitsui Chemicals, Inc., Murata

has successfully developed a stable production method for a PLLA film with sufficient piezoelectric

characteristics to enable sensing.

Piezoelectric property is displayed when a molecular group generating permanent dipoles, such as C=O

within molecules, shifts its positions slightly influenced by an external electric field. PLLA displaying

its piezoelectricity from characteristics of the oriented high-order molecular structure does not require

a poling process. The piezoelectric constant of PLLA shows very little aging degradation.

Implementation as Displacement Sensors

While PLLA's piezoelectric constant (piezoelectric dconstant) is around 7 - 12pC/N, much

smaller than that of PZT, its dielectric constant is also very small at approx. 2.5, making its

piezoelectric output constant (= piezoelectric g constant

whereg=d/εT ) large and its sensing sensitivity high. In terms of the

piezoelectric output constant, PLLA is roughly equivalent to polyvinylidene fluoride (PVDF) whose

piezoelectric constant is more than four times as much as PLLA. When exposing piezoelectric PLLA to

an electric field, it displays unique deformation from the reverse piezoelectric effect from shear

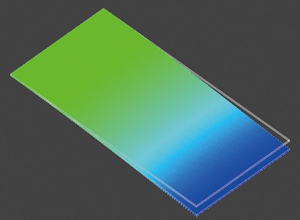

piezoelectricity (d14 ) as shown in Fig. 2. Helical molecules line up roughly

in the drawing direction of the film. The original shape of the film is illustrated with dotted

lines. As an electric field is applied depth-wise from the back of illustration to this film,

deformation illustrated by solid lines occurs (exaggerated for a purpose of illustration) .

Fig. 2 Deformation by shear piezoelectricity

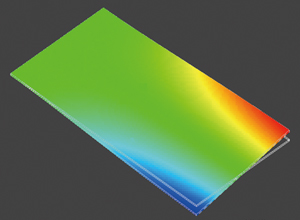

Figure 3 indicates a difference in simulated deformations by reverse piezoelectric effect for different

molecular orientations in films. Film A is cut into a rectangle at a 45 degree angle from the molecular

orientation, while film B is cut into a rectangle along the direction of the molecular orientation. Each

of them is adhered to a PET film with one short end fixed in a cantilever fashion. By applying voltage to

the electrode formed on the principal surfaces of each film, an electric field is applied. As a result,

film A is bent and film B is twisted. Retracing these phenomena in a reverse order, film A can be made

into a bend sensor and film B can be made into a twist sensor.

A major characteristic of shear piezoelectricity is this ability to alter the sensing mode just by

changing the angle the original film is cut. These sensors sense only the deformation they are meant to

sense even when they are adhered to each other. For example, the bend sensor generates almost no charge

when it is twisted, because the charge distribution occurring on the electrode surface is cancelled

equivalently. The same goes for bending the twist sensor.

Film A

Film B

Fig. 3 Cut angle and sensing mode

Proposing Application Devices Capitalizing on Characteristics

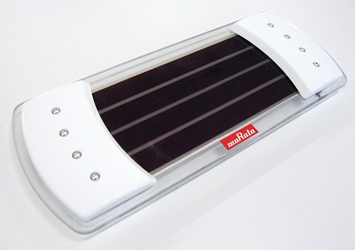

Leaf Grip Remote Controller

The Leaf Grip Remote Controller (Fig. 4) controls a TV through simple bending and twisting motions.

There are two acrylic plates layered in its central area, one affixed with a bend-sensing

piezoelectric film and the other affixed with a twist-sensing piezoelectric film. A flexible

photovoltaic power generation device (dye-sensitized photocell) is inserted between two plates (Fig.

5) .

The power-generating efficiency of the photocell is unaffected because of the high transparency of

piezoelectric films. Rechargeable batteries, power-supply circuits, transmission circuits and sensor

circuits are built into grips on both ends. A photocell generates power whenever exposed to light and

power is stored in rechargeable batteries, eliminating the need for exchanging of batteries.

This remote controller can control a TV with the following actions.

- Lightly shaking: Turning the power ON or OFF

- Twisting: Switching channels

- Bending: Adjusting the volume

- Quickly twisting twice: Switching the input source

This remote controller is an experience a world apart from conventional remote controllers with its

intuitive operations without having to look for buttons. For example, a senior user would be freed

from putting on a pair of reading glasses just to find correct buttons to push.

Fig. 4 External view of the Leaf Grip Remote Controller

Fig. 5 Cross-sectional view of the Leaf Grip Remote Controller

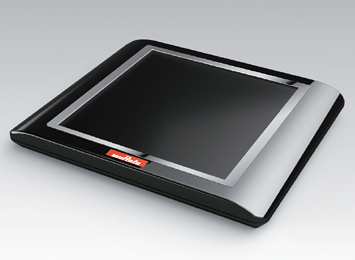

Touch Pressure Pad

Touch pressure pad (Fig. 6) realizes XYZ 3-axis sensing by adding pressing force sensing to a

conventional capacitance type touch-panel. An electrode to detect voltage generation from the pressure

was composited to the conventional capacitance type position-sensing electrode on both sides of the

bend-sensing piezoelectric film. Slight warp in the touch panel from pressure can now be sensed (Fig. 7)

.

With PDVF, it was unable to sense the pressure exactly, since its pyroelectric property caused voltage

generation from the temperature of the fingertip. Absence of pyroelectricity in PLLA, on the other hand,

allows for exact pressure sensing. Pressure sensing is realized not by adding other sensors such as a

distortion sensor to the conventional touch panel, but rather the touch panel itself can detect the

pressure, therefore making its construction very simple. Another advantage of PLLA is its excellent

light transmittance when implemented to a touch panel having transparent electrodes.

Fig. 6 External view of a touch pressure pad

Fig. 7 Sensing principle of a touch pressure pad

Final Remarks

Displacement sensors, triggering voltage fluctuation from a bend or twist displacement, may be implemented

to intuitively controlled operations of game machines and care equipment. It is also applicable for

kinetically controlling (Fig. 8) futuristic mobile phones. The touch pressure pad technology, implemented to

the touch panel itself, can help detect bend and twist actions. This touch panel, equipped with conventional

gesture recognition in addition to bend and twist, is capable of more advanced intuitive HMI. Sensors used

in equipment controlled by hand must be made with non-pyroelectric material such as PLLA to prevent

temperature-related detection errors. We intend to continue developing sensor products that can bridge

between people and machines in all kinds of situations.