Power Generation Characteristics of Multilayer Oxide-Metal Composite Thermoelectric Modules and Applications in Energy Harvesting

Shuichi Funahashi, Takanori Nakamura, Keisuke Kageyama

[JOURNAL OF APPLIED PHYSICS 109、124509 (2011) ]

In thermoelectric power generation, thermal energy can be directly converted into electrical energy using the physical phenomenon known as the Seebeck effect*. We successfully developed materials with superior thermoelectric characteristics using oxide materials that do not contain rare elements as their primary component, and this enabled us to develop a monolithic multilayer thermoelectric module using the same fabrication process as multilayer ceramic capacitors.

This module generated 100µW output at a temperature difference of 10°C and was capable of operating a temperature sensor and wireless module. This technology for generating power at small temperature differences is expected to be used as an energy harvesting technology for running devices by generating electricity from the surrounding heat for application in sensor network devices for enabling them to be driven semi-permanently without wires or batteries.

Thermoelectric conversion technology is used to directly convert heat to electricity, and it is expected to become an effective way of using waste heat, natural heat, and other heat sources. In power generated by the thermoelectric conversion elements, electricity can be efficiently generated even from slight temperature differences with small fluctuations due to scale by utilizing the physical phenomenon known as the Seebeck effect. Moreover, because there are no driving parts in the power generation system, this technology is not susceptible to mechanical breakdowns and provides long-term reliability.

The power generated by thermoelectric conversion elements is indicated by the dimensionless figure of merit ZT shown in formula (1) , which shows that the preferred conditions are a high Seebeck coefficient α and a low electrical resistivity ρ and thermal conductivity κ . However, these factors are interlinked because they are all electron functions, and so the material composition must be adjusted to obtain the optimal electron density. Currently, the highest ZT in a room-temperature environment is obtained with a material whose primary component is Bi2Te3 , and its ZT value is approximately 1.2.

The top range of the Seebeck coefficient for thermoelectric materials is approximately 100 to 200µV/KFor this reason, normally, multiple modules are connected in series and used in a π-type module structure to obtain a practical voltage. In contrast to the π-type structure, the monolithic multilayer module that we have developed uses n-type thermoelectric material and p-type thermoelectric material shaped into thin sheets that are stacked and sintered in a single chip to form the element structure shown in Fig. 1. The modular structure with this type of configuration can provide the characteristics below.

- No need for electrodes connecting the thermoelectric elements

- No need for spaces for ensuring insulation between elements

- High surface efficiency even when the number of elements is increased

- High voltages are easily obtainable even at low temperature differences

Fig. 1 Structure of the monolithic multilayer oxide-metal thermoelectric module

The monolithic multilayer module that was fabricated in this study used La-doped SrTiO3 as the n-type material, Mo-additive Ni as the p-type material, and partially-stabilized zirconia as the insulator material. In terms of their thermoelectric characteristics at room temperature, the n-type material and p-type material used in this study exhibited Seebeck coefficients of -153µV/K、+20µV/K, electrical resistivities of 1.8 x 10-5Ωm and 1.3 x 10-6Ωm, and thermal conductivities of 5.2 W/mK and 6.6 W/mK, respectively. As shown in the thermal shrinkage behavior of these materials in Fig. 2, these materials were adjusted so that shrinkage started from around 1200°C for enabling sintering without pressure application.

Fig. 2 Shrinkage characteristics of component materials

The fabrication process of the monolithic multilayer module used a procedure identical to that for multilayer ceramic capacitors. First, thermoelectric material sheets were manufactured using the doctor-blade method to a thickness of 0.12 mm for n-type and 0.03 mm for p-type. The insulator material was prepared by mixing the material powder and an organic solvent using a three-roll mill to form a paste, and then a screen printing method was used to form a thickness of 0.006 mm on each green sheet. These sheets were stacked alternately in 50 pairs, pressed, and then cut to the predetermined size to obtain green chips. After first removing their organic components in an atmosphere of 400°C, these green chips were sintered for two hours at 1300°C in a reductive atmosphere. The power generation performance of the module was evaluated by applying a temperature difference of 10°C to 360°C in an atmosphere (with the cold side fixed at 20°C) and measuring the open voltage at no load and the output when a load was connected.

Glossary

* Seebeck Effect:

The Seebeck effect is the phenomenon where joining the ends of two different types of conducting wires to form a closed circuit will generate an electromotive force when different temperatures are applied to both junctions. This was discovered in 1821 by the German physicist Thomas Johann Seebeck.

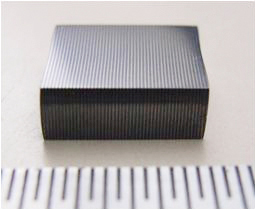

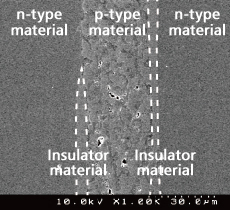

A photo showing the appearance of the fabricated module is shown in Fig. 3. The module was precisely crafted with a size of 5.9mm x 7.0mm x 2.6mm with no visible cracking, chipping, unpeeling between layers, or other defects, and had a relative density of at least 95%. A scanning electron microscope (SEM) image of the junctions of the thermoelectric materials in this module is shown in Fig. 4. In this figure, the area surrounded by dotted lines is the insulation layer. As shown in the figure, there is no noticeable elemental dispersion between the layers, and the junctions of the thermoelectric materials are also clear.

Fig. 3 Photograph of monolithic multilayer module

Fig. 4 SEM image of p/n junctions

The temperature dependence of a no-load voltage of the fabricated module is shown in Fig. 5. As shown in the figure, the no-load voltage increases linearly as the temperature difference increases, and a value of 0.6 V is obtained at ⊿T=100°C, and 2.0 V is obtained at 300°C. For the power generation characteristics when connected to a load, a maximum value of 187 mW (at 0.15 A) is obtained for a temperature difference ⊿T=360°C. The generated power per unit area calculated from this value and the module heat transfer area was 450 mW/cm2. To develop this thermoelectric module for energy harvesting applications, the power generation performance at small temperature differences must be evaluated. Therefore, the generated power at ⊿T=10°C (hot side: 30°C, cold side: 20°C) was evaluated, and the results of this evaluation are shown in Fig. 6. As shown in this figure, the voltage at no load is 52 mV, and the maximum output was 105 µW (at 4 mA).

Fig. 5 Temperature characteristics of no-load voltage and maximum output

Fig. 6 Power generation characteristics at temperature difference of 10°C

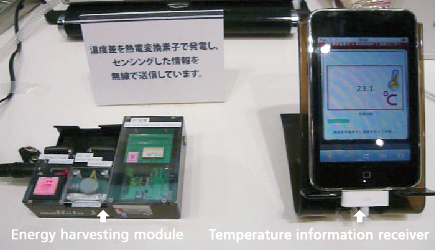

Devices that operate using energy harvesting technology generally have two modes of operation. In one mode, the generated power exceeds the power consumption of the load so that continuous operation of the device is possible. In the other mode, the generated power is less than the power consumption of the device, and so the generated power must be stored in a capacitor, and the power is supplied to the load after a certain amount of charge is built up. For this process, the capacity of the capacitor storing the charge must be selected to match the characteristics of the operating device. For this study, we fabricated an integrated wireless sensor device as shown in Fig. 7 for using a temperature sensor and communication module as the load.

This device used a heater of approximately 40°C as the heat source and had a structure that enabled heat that passed through the thermoelectric module to flow to the casing. In this design, in an external environment of 25°C, a temperature difference of 10°C was obtained in the monolithic multilayer module. Temperature measurements were conducted once about every 10 seconds with this configuration, and it was possible to send this information wirelessly. To enable operation under additional loads such as for operation under lower temperatures, shorter operation intervals, and for driving of multiple sensors, the output characteristics of the module will have to be improved, and advancements are also needed for improved conversion efficiency of the materials, reduced loss in the module, and other issues.

Fig. 7 Energy harvesting module (Thermoelectric power generator + temperature sensor + wireless module)

Original Paper: "Monolithic oxide-metal composite thermoelectric generators for energy harvesting"